Request info

Fill in the form to request information for placing an order, availability, pricing and/or logistics.

Pay online through PayPal

Flavor

Delicate cocoa base with very mild fruit and floral notes of spice and light wood. Very low bitterness and astringency. Overall soft and delicate profile.

Physical aspects

Moderate size beans with 85-95 beans per 100 grams. Mechanically sorted to remove flat beans and other defects.

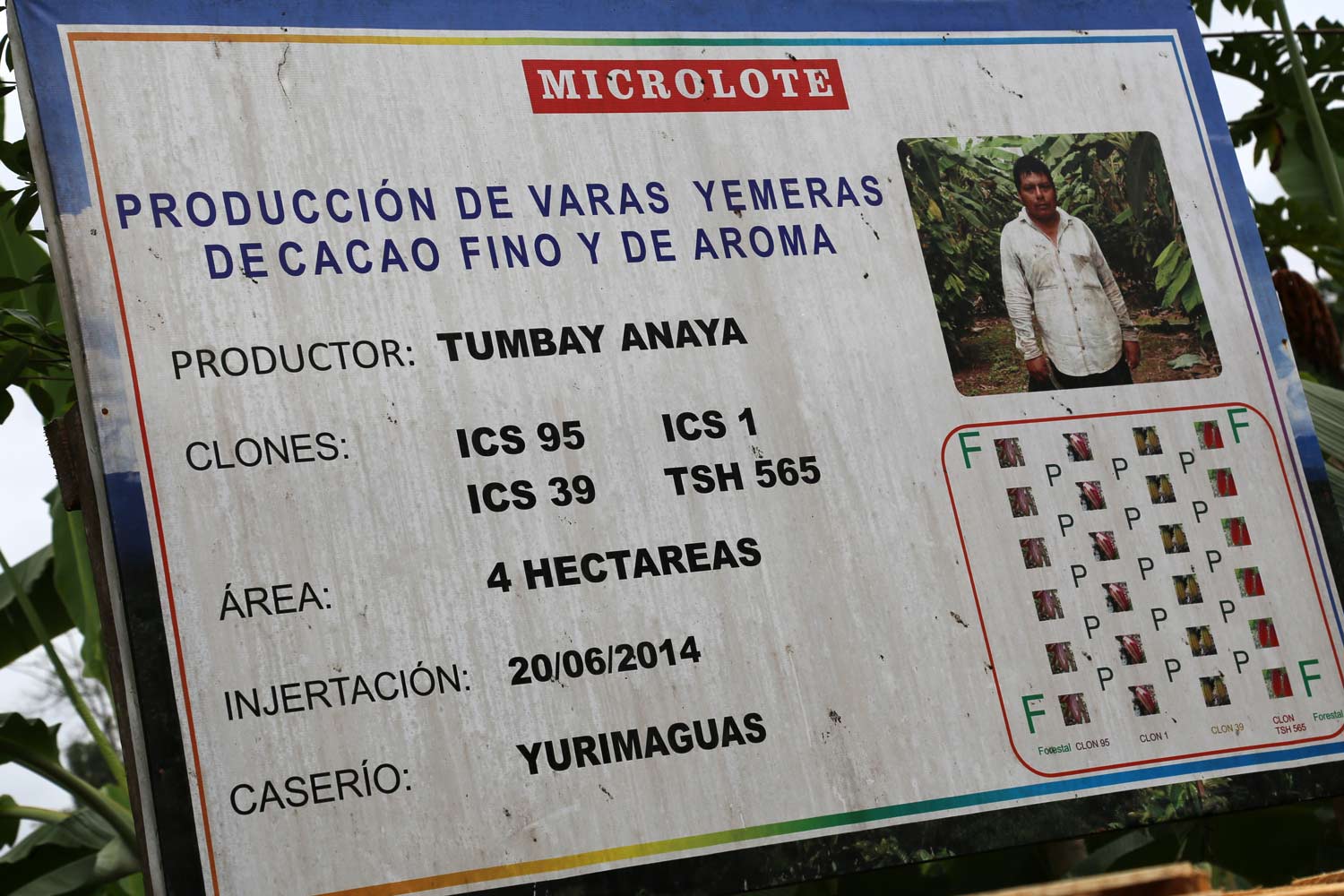

Genetics/Cultivars

Mostly Trinitario clones (ICS-1, ICS-39, ICS-95, TSH-565), with locally selected cultivars and older seedlings of native Peruvian origin.

Certifications and Trade Relationship

Organic, uncertified. Direct trade.

Notes

URC works with communities to develop quality standards for wet cacao. Only fresh cacao opened the morning of pick-up is sourced and loaded into fermentation boxes by nightfall.

Source Details

Raw Material Source & Climate

Numerous farming communities in the Ucayali and Huánuco regions with a range of terroirs. Fresh, wet cacao is collected in clean rice sacks from numerous communities in the Pucallpa and Tingo Maria areas, and transported to a central processing center that is owned and operated by Ucayali River Cacao. The cacao collected from these two areas is fermented separately but is blended after drying and grading to create the balanced profile of Ucayali River Cacao.

These regions have an Amazonian climate with high rainfall throughout the year with a somewhat drier season from May through August, but there is little variation in average temperatures. Tingo Maria is a higher elevation region (~2000’ ASL) than Pucallpa (~500’ ASL), and has cooler, misty climate. Farms in Tingo Maria are in the hills bordering the Huallaga River. The flatter terrain in the Pucallpa area is along the banks of the Aguaytia and Ucayali Rivers. All of three of these rivers are tributaries of the Amazon and are known to have wild stands of cacao trees.

Ucayali River Cacao supports farmers by purchasing wet cacao at premiums averaging 10% over the local market rate for an equivalent amount of dry weight.

Owners, Management Employment

Ucayali River Cacao is operated through a collaboration between three parties with expertise in food production. Family business Grupo Megamar S.A. has a long history in seafood production and is operated by brothers-in-law Marcos Blitchtein and Isaac Falkon Stern. Ucayali River Caca0, SAC was founded in 2017, so Megamar S.A. is no longer being used for the cacao business. Marcos and Isaac have a long and productive working relationship with Robin Jordan – an expert at high quality seafood processing. Robin moved back to his wife’s home country of Peru and partnered with Marcos and Isaac in a new business venture based on cacao production. Before production, the team sought an experienced collaborator for developing cacao production facilities and protocols, and Dan O’Doherty of Cacao Services, Inc. joined the team. Ucayali River Cacao was founded to deliver ultra-premium cacao (i.e., exceptionally regulated/executed standards for post-harvest handling) to the specialty, bean to bar chocolate market.

Robin Jordan, extended family and members from the local community run the facility. Residents of the various farming communities that we source from receive income through coordination and collection of fresh cacao during the harvest season.

Farming Communities

In each agricultural area, community members are paid for their regular assistance in coordinating harvesting and pickup of cacao every two weeks. Each farmer is paid a premium price above the local market at the farmgate.

Most local farmers have 1-2 hectares of cacao trees – about 2000 trees in total, but a few farms are as large as 5-6 hectares.

Growers in these regions have progressive agriculture practices for cacao cultivation and tend to maintain organic polyculture plantings of cacao, bananas, and other fruit under the light shade of tall timber trees.

Local cacao farmers have mastered practical and responsible agricultural skills such as grafting, pruning, and disease management. Trees are pruned regularly to allow for efficient harvesting, reduction of fungal disease, and maintenance of tree vigor.

Harvest Season

Trees bear the highest quality fruit from April to August in most years, but it appears the 2018 harvest will start as early as March.

Food Safety Tests

Laboratory details

Microbial

- SPC: 2,200 cfu/g

- Coliforms & E. coli: <3 mpn/g

- Salmonella: Negative

- Listeria: Negative

- Yeast: <10 cfu/g

- Mold: <10 cfu/g

Cadmium

- Whole beans: 0.84 mg/kg (ppm)

Ochratoxin A

- OTA: none detected

Roasting & Processing Suggestions

Lighter roasts bring out some mild dried/red fruit notes. Darker roasts yield stronger base cocoa notes and nutty character.

Post-Harvest Handling

Site & Design

The post-harvest facility is in a rural agricultural area of the Curimaná district, and is owned by production manager, Robin Jordan. Although the wet Amazonian climate presents a challenge for drying, a brand-new fermentation facility was designed to foster effective natural drying and produce an exceptionally product with high quality and consistency.

Fermentation

Paired box fermentation. Cedro (Cedrela odorata) wood boxes with ~500 kg capacity. The fermenting mass is turned back and forth between two boxes until fermentation is complete. Wet cacao grown in this area has unusually high pulp content, and raw material is pre-condition by draining in mesh sacks for at least 8 hours before loading into boxes. Total duration of fermentation is 6.5 days.

Drying

All cacao is sun dried on waist-high drying tables covered with plastic mesh to allow sufficient airflow. High-walled polyethylene tunnels cover all drying structures. Gradual drying is practiced during the first three to four days to allow volatilization of excessive acidity and to allow chemical reactions started in fermentation to continue. After the initial drying period, beans are dried until moisture content reaches 6.5-7%.

Grading

On every harvest day, each fermentation box is assigned an ID number. After fermentation and drying, cacao is sampled from each ID number and is evaluated on internal standards developed by Ucayali River to produce a signature flavor profile. Only cacao that meets our quality standard is retained, aged, and blended for our export grade product. All blended lots are evenly mixed and identified by a colored tag sewn to the bottom of each jute sack.

Blending

Once the harvest season is over, we evenly blend all export grade beans so that once chocolate makers determine a roasting profile and processing protocol, it can be predictably applied to each sack contained in a single order of cacao. All blended lots are evenly mixed and identified by a colored tag sewn to the bottom of each jute sack.

Samples

After blending, we reserve enough samples from each lot to distribute to chocolate makers. As a result, we guarantee that any order will be an exact match to the sample provided.